Packaging is the planet’s fastest-growing source of plastic waste: almost half of new plastic protects a product for mere minutes before landing in landfill or waterways. Analysts forecast the sustainable-packaging market will jump from $314 billion in 2025 to $558 billion by 2034, according to a 2025 Grand View Research analysis. According to Statista, 40 percent of Americans in 2024 said they’ll pay extra for greener packaging. Below, we profile the 5 best eco-friendly custom packaging companies poised to meet that demand in 2025.

Advertisment

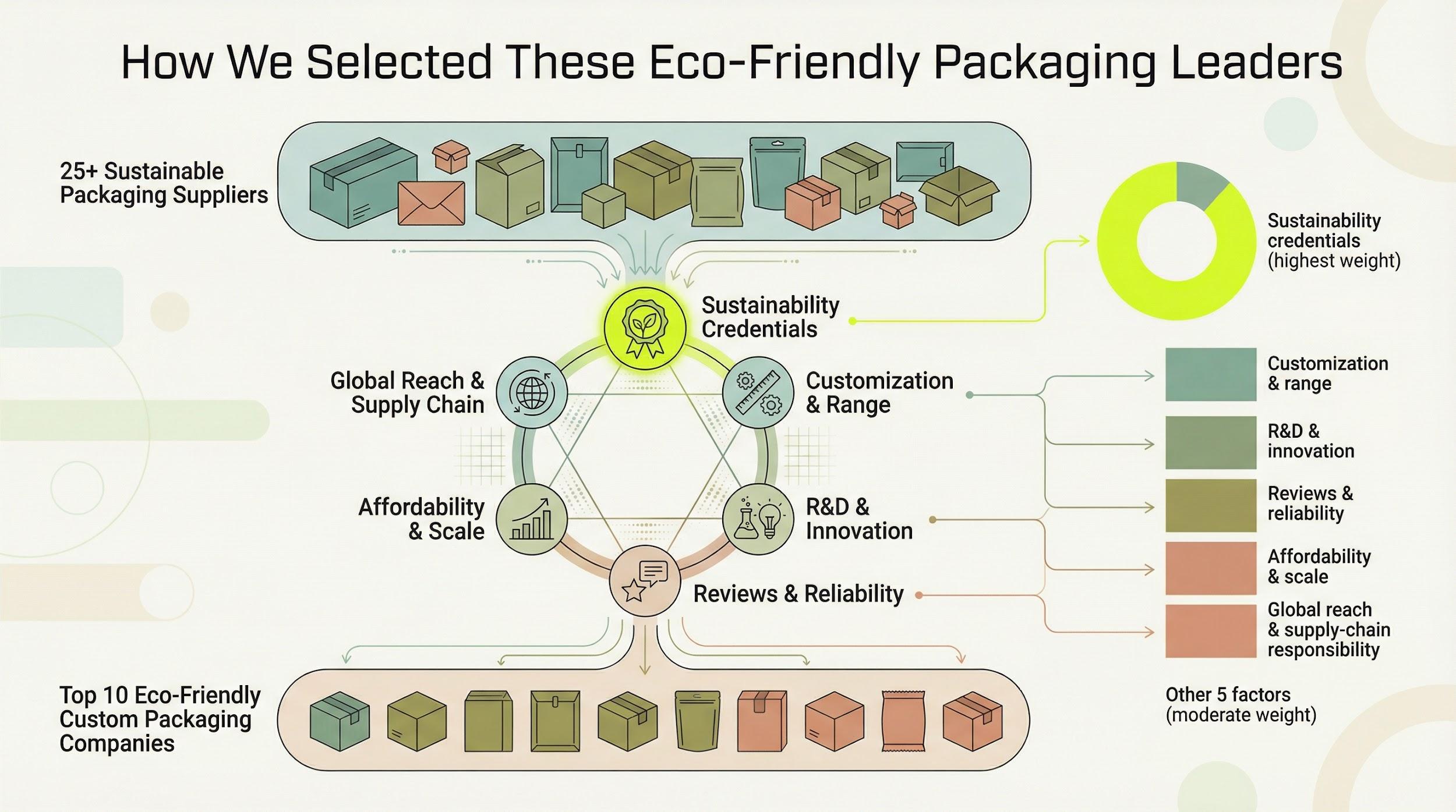

We started by mapping the sustainable-packaging field, logging 25 suppliers that appear consistently in trade journals, award lists, and investor decks. That exercise created a living spreadsheet of established manufacturers, agile startups, and material scientists across North America, Europe, and the Asia-Pacific region.

Next, we scored each company on six factors that matter most to brand owners in 2025. Sustainability credentials carried the most weight because recycled content and third-party certifications are the first questions buyers ask. Close behind came customization and product range; if a supplier cannot match your spec sheet, nothing else counts. Research progress and real-world customer reviews formed the next tier, providing credit for forward-thinking R&D and day-to-day reliability. Affordability and scalability followed, and we rounded out the list with global reach and supply-chain responsibility.

Each factor sat on a 100-point scale that reflected its business impact. We cross-checked data points such as B Corp status, iF Design wins, and Trustpilot scores with public filings and client case studies. The result is a ranking that blends hard numbers with practical insight, so you can choose a partner with confidence rather than guesswork.

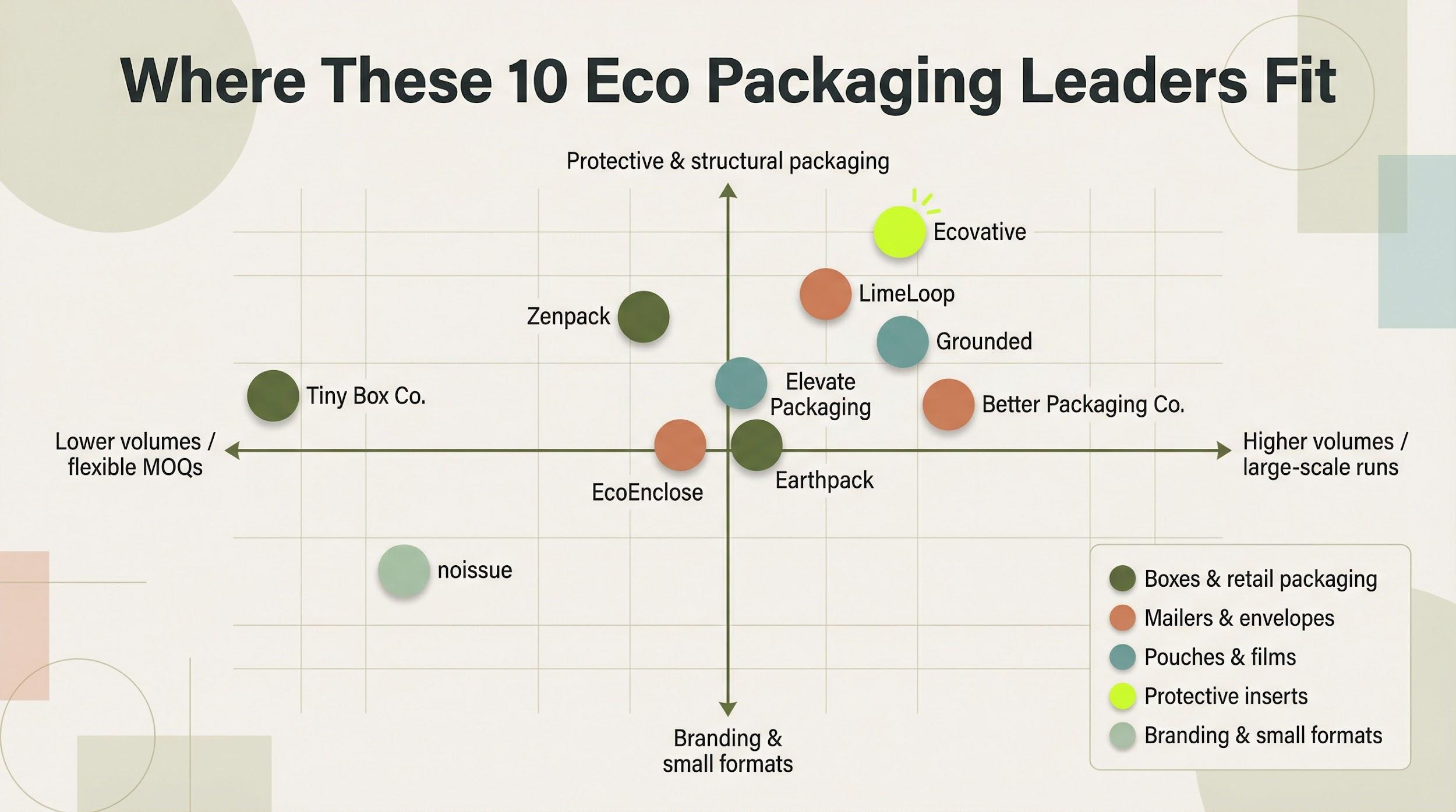

You have the selection logic; the grid below lets you match each supplier’s specialty to your packaging need, then explore the detailed profiles that follow.

Company (HQ) | Founded | What they’re best at | Stand-out eco credential | Customization sweet spot |

Zenpack (USA) | 2015 | Turnkey design-to-manufacture boxes | iF Gold Design Award 2024, FSC paper | Fully bespoke, low MOQs |

Grounded Packaging (AUS) | 2018 | Sustainable pouches & films | Climate-neutral, UN SDG aligned | Prototype runs, digital print |

Earthpack (USA) | 1989 | Recycled retail bags & boxes | 100 percent recycled paper, soy inks | Bags from 250 units |

LimeLoop (USA) | 2018 | Reusable shipping pouches | Upcycled vinyl, 200-trip lifespan | Branding available on rental fleet |

Ecovative (USA) | 2007 | Mycelium protective inserts | Home-compostable, Plastic Free certified | Custom molds, negotiated MOQs |

Treat this table as a cheat sheet. Need low-volume branded tissue? noissue is a fit. Shipping fragile electronics? Ecovative’s mushroom foam safeguards gear without plastic peanuts. Keep the grid handy as we explore each pick in the next section.

Advertisment

Zenpack operates more like a packaging think tank than a printer. Its end-to-end custom packaging solutions knit strategy, design, manufacturing, and logistics into one continuous workflow, so you brief once and receive everything from concept sketches to pallet-ready cartons.

Sustainability drives every step. The team defaults to FSC-certified boards, soy inks, and right-sized structures that cut grams and emissions. That approach earned an iF Design Gold Award in 2024, according to a PR Newswire release.

Start-ups value minimum orders of around 300 units, while enterprise clients rely on Zenpack’s Asia-US network to scale without middle-agent mark-ups. When you need premium unboxing that also meets a life-cycle audit, Zenpack delivers.

Flexible films are recycling’s problem child, yet they dominate snack aisles. Grounded addresses the issue with a lab mindset, offering compostable or mono-material pouches that still keep coffee aromatic and granola crisp.

Their differentiator is Impact, a software dashboard that models carbon, water, and end-of-life outcomes for every material choice. You see, in real numbers, how a home-compostable film compares with a recyclable PE laminate before you approve production. Decisions shift from gut feel to data.

On the production floor, digital printing unlocks vibrant edge-to-edge graphics without plate fees, and prototype runs as low as 5 000 units help startups test shelf appeal without draining cash. When volume spikes, Grounded’s Asia-Pacific plants scale to meet national-retailer demand.

For brands wrestling with multilayer plastic but unwilling to risk product freshness, Grounded provides a practical bridge to circularity. Flexible no longer has to mean disposable.

Long before “zero waste” appeared in investor decks, Earthpack printed kraft bags for surf shops along the California coast. The company still champions recycled paper, but the scale is now national and the catalog covers rigid gift boxes, apparel mailers, and tissue.

In-house designers turn a rough logo into retail-ready packaging that feels custom, not off-the-shelf. Minimum orders can dip to 250 bags, yet the same presses push out large runs for global apparel chains, showing that recycled paper performs at any volume.

Soy inks keep items curbside recyclable, and local manufacturing trims freight miles. Add 30-plus years of supply-chain stability, and you get a partner that delivers season after season, even during cardboard shortages. For brick-and-mortar brands seeking eco bags with boutique aesthetics, Earthpack remains the gold standard.

Single-use packaging ends up in bins; LimeLoop mailers come back for round 200. The rugged envelope, stitched from upcycled billboard vinyl and cotton, carries an IoT tag that records every trip.

Here is how it works. You ship an order in a LimeLoop pouch. The customer flips it inside out, reveals a prepaid return label, and drops it in any mailbox. The pouch pings LimeLoop’s dashboard, so your operations team can track location, condition, and carbon savings in real time. Inventory stays visible, losses stay low, and sustainability reports fill themselves.

Brands can lease or buy fleets, then add custom graphics for a branded unboxing that repeats again and again. Early pilots show a 70 percent cut in emissions compared with ten cardboard boxes, making reuse a numbers win as well as an ethical one. If your product cycle already includes returns or rentals, LimeLoop bolts on with minimal friction and turns logistics into a circular story customers love to share.

Fragile goods used to rely on Styrofoam. Ecovative grows a better answer. The team mixes agricultural waste with mycelium—the root network of mushrooms—then lets it grow in custom molds for about a week. Heat finishes the process, creating a lightweight insert that cushions like foam and composts in 45 days.

The material is renewable, nontoxic, and naturally fire-retardant. Global brands from Dell to IKEA have trialed it for electronics and furniture, proving the concept at scale. Yet minimums stay flexible; wineries and skincare labels commission smaller runs for bottle shippers and gift sets.

Because inserts grow to shape, you avoid die fees and cut off-cuts to zero. Customers can toss the packaging in a backyard garden, turning unboxing waste into soil nutrients. It is circular you can hold in your hand—and a memorable story long after the product is in use.

What makes packaging truly eco-friendly?

Eco-friendly packaging minimizes environmental impact across its full life cycle. That usually means using recycled or renewable materials, avoiding toxic inks and adhesives, reducing excess material through smart design, and ensuring the packaging can be recycled, composted, or reused after use. Third-party certifications such as FSC, BPI, OK Compost, or B Corp help verify these claims.

Is sustainable packaging more expensive than traditional packaging?

Upfront costs can be slightly higher, especially for compostable or innovative materials. However, many brands find the total cost evens out—or drops—once they factor in reduced shipping weight, lower damage rates, customer loyalty, and fewer returns. As volumes scale, eco-friendly options often reach price parity with conventional packaging.

What certifications should I look for when choosing a sustainable packaging supplier?

Key certifications include FSC (responsible paper sourcing), BPI or OK Compost (compostability), B Corp (overall social and environmental responsibility), and Climate Neutral certification. Reliable suppliers are transparent and will provide documentation without hesitation.

Can eco-friendly packaging still be customized and branded?

Yes. Most leading sustainable packaging companies offer full customization, including size, structure, printing, and finishes. Digital printing has also lowered minimum order quantities, making branded eco-packaging accessible even for startups and small businesses.

What are low-MOQ options for small or emerging brands?

Companies like noissue, Tiny Box Company, Zenpack, and Earthpack specialize in low minimum order quantities, sometimes starting as low as 250 units. These suppliers are ideal for pop-ups, test launches, seasonal campaigns, or early-stage brands.

Advertisment

Start with the problem you need to solve, not the materials you admire. Are breakages cutting margins? Ecovative’s mushroom inserts lower returns. Fighting high return rates? LimeLoop’s reusable pouches fold reuse into your shipping workflow. Once the pain point is clear, match it to the specialty column in our comparison table.

Second, run the numbers. Calculate annual order volume and cash-flow limits. If you ship only a few hundred mailers each month, noissue or Tiny Box keeps inventory lean. Handling five-figure monthly units? Grounded or EcoEnclose scales without forcing a supplier switch later.

Third, check the paperwork. Ask for copies of every certification—FSC, BPI, or B Corp. Trusted partners share them without an NDA. While you wait, order a sample kit and test it in real conditions: does the compostable pouch survive your heat sealer, or does the ink scuff during transit?

Finally, loop in marketing. Smart packaging doubles as brand storytelling. Zenpack’s unboxing moments, Better Packaging’s compostable labels, and Elevate’s certification badges turn raw sustainability data into shareable content.

Advertisment

Pin it for later!

If you found this post useful you might like to read these post about Graphic Design Inspiration.

Advertisment

If you like this post share it on your social media!

Advertisment

Want to make your Business Grow with Creative design?

Advertisment

Advertisment